Robotic arms assembling an EV battery pack at a commercial scale plant. Catalyst is helping companies reach this stage and learn by doing.

If our Discovery-stage work helps accelerate the earliest-stage of innovation through Fellows, Explorers, and Innovation Workshops, and our Development work accelerates climate-tech company-building through groundbreaking venture funds, then you can think of our Deployment work as accelerating late-stage innovation — what’s often called learning-by-doing, which is what happens when projects get developed and built, processes improve, and costs come down over time.

Because at this stage, innovators need more than just financing. They need expertise.

Innovators need people who understand how to get sites, permits, easements, interconnections, and regulatory approvals. They need business development people looking for customers, securing critical feedstocks and power. And they need people advancing the project design, engineering, procurement, and construction plans, including identifying key equipment and contractors.

Finally, they need the team to execute complex construction while adhering to timelines and strict budgets. Catalyst

provides not only critical funding, but also this infrastructure expertise to lower the engineering and other operational risks of promising technologies. And we unite companies with key stakeholders such as investors, off-takers, and governments to enable demonstrations or build commercial-scale projects.

Aerial view of electric substation. Electric substations like this can help ensure new technologies are powered by clean energy

Third, while developers of these projects should court early customers, they should be careful about locking in pricing until the design of their project is mature and the full costs are known. As mentioned earlier, project costs typically increase as the design matures, and this must be considered before a final investment decision can be made.

Fourth, projects need to show reliable access to feedstock and clean electricity supply. It’s impossible to attract long-term investors to projects that can’t show they have a stable supply of the raw materials necessary to make the technology work. What’s more, it’s not worth investing in a climate project that negatively impacts the environment. That’s why it’s critical for these technologies to be supported by clean electricity.

Workers installing solar paneling on the roof of a large warehouse

Finally, developers should look at how all the pieces of the project fit together and ask themselves, “Can this support my nth project?” This goes back to our first lesson: Set yourself up for long-term success.

Emerging climate tech should not be a business of one-offs. By definition, we need technology and agreements that can scale and go the distance, shifting markets and modeling success for other players. Emerging technologies should try to share information, standards, and best practices where possible. This helps ensure broader industry success by improving tech reliability and preventing other companies from making avoidable mistakes.

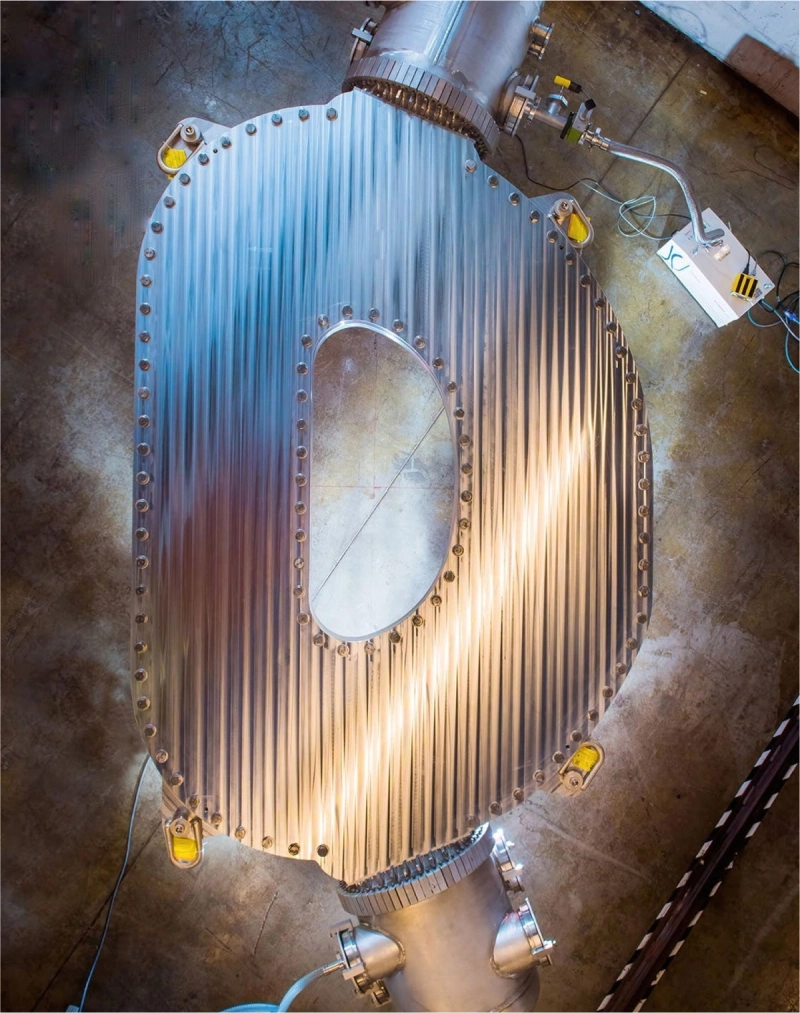

A fusion magnet manufactured by Commonwealth Fusion Systems using a new high-temperature superconductor

Timing was another square peg in a round hole. Most venture capital firms invest in startups hoping they’ll make their money back within a decade, a reasonable expectation when you’re investing in software. Roughly twenty-six months elapsed between Microsoft’s hiring of its first Windows programmer and when the first Windows 1.0 floppy disks hit the shelves.

But fusion power plants are not lines of code. Nor are carbon-free steel factories or advanced car batteries. These technologies can take years, even decades, to translate from cutting-edge science to deployable and scalable solutions.

Climate tech is also typically “tough tech” — applications of science and technology to the world's biggest problems — and has similar structural obstacles to getting off the ground. Namely, pretty slim margins, which are usually not compatible with a VC firm seeking huge returns for a small slice of their portfolio.

These kinds of tech also have fewer intermediate checkpoints to make sure they actually work. Think of an industry like pharmaceuticals, which has a standard progression of four different trial phases — there’s nothing really comparable for tough tech. It’s often difficult to tell how well a company will do until it’s literally on the market.

ZeroAvia HyperTruck Ground Rig Tests It's HyperCore Motor Technology

For all these reasons, by the mid-2010s, Bill Gates and Breakthrough Energy’s founding team realized that, if climate tech was to benefit from the company-building, scaling power of VC, then it would need to be a pretty different kind of VC.

It would have to be a VC operation that was built for the specific purpose of supporting decarbonization technologies, which meant it would have to be far more patient, and more technical.

Any VC firm investing in climate would also need to get comfortable taking enormous risks and be prepared to deal with the policy and capital intensity specific to climate tech.

A cement blocked created using Brimstone's carbon-negative process

Of course, all VC firms are comfortable with some measure of risk. They recognize that only a small fraction of their portfolio companies will return a profit. But climate venture capital is different from the rest in one important respect: There’s a big invisible countdown clock hanging over its work like a specter. Investors and their startup companies aren’t trying to meet an artificial financial deadline; they’re racing against a real climate deadline, as more and more greenhouse gas (GHG) emissions are released into the Earth’s atmosphere.

Given the narrow window we have to solve climate change, it doesn’t make sense to invest resources in a company that will abate a small amount of GHG emissions — even if their technology is a surefire bet. We need to make big (albeit well-informed) bets.

At Breakthrough Energy Ventures, we concluded that any startup worthy of investment needed a conceivable pathway to reducing 500 megatons per year of GHG emissions — roughly one percent of all global annual emissions.

Six years later, Breakthrough Energy Ventures has invested nearly $2 billion in over 100 such companies . It’s still too early to measure how much emissions these companies, individually or collectively, have abated. (We plan to include those metrics in future versions of this report). But much of the anecdotal evidence we have shows that our model is working.

Antora's thermal energy storage site in Fresno, California

It was immediately clear to the BEV team that Antora had a powerful idea for a rapidly scalable product, an enormous market opportunity to decarbonize industrial heat and power, and an exceptional team with world-class technical expertise. What they needed was private capital and support to take their game-changing idea from a prototype to a commercial-ready product. That is what Breakthrough Energy Ventures delivered, co-leading Antora’s Series A and bringing total funding up to $50 million.

Antora is electrifying heavy industry with zero-carbon heat and power

BEV’s Christina Karapataki, who joined Antora’s board, and Sila Kiliccote, a former startup CEO, who joined as a board observer, are now trusted partners to Andrew, Justin, and David on all aspects of the business, including product development and the commercial roadmap. They have connected Antora with major renewable power suppliers, marquee customers, and critical commercial and financial partners. And the robust policy and communications support that Breakthrough offers has helped Antora navigate the intricacies of the energy and industrial sectors.

Two years after leading Antora’s Series A, the catalytic impact of our investment is clear. This fall, Antora launched its first commercial-scale thermal battery at an industrial site outside Fresno, California, which Bloomberg called “a major step toward its goal of weaning heavy industry off fossil fuels.” With BEV’s support, Antora is now ready to scale. They recently opened a thermal battery manufacturing facility in San Jose, California that will have its first battery modules rolling off the line in 2024 to serve major industrial decarbonization projects. And they have additional customers lined up for a proven product that’s poised to decarbonize industrial sites across the United States and around the world.

Forklift moving carbon blocks

In addition to storing electricity for a longer period of time, LDES could also enable the decarbonization of other sectors, such as industrial heating processes. Antora is working on exactly that, storing renewable electricity from sources like wind and solar as heat in solid carbon blocks.

These are just some

of the innovative companies working to solve the storage problem. But we also have to focus on scaling and deploying these technologies.

Scaling LDES presents several challenges. Most LDES manufacturers are either startups or newly-public companies with limited experience in large-scale production. It’s also hard to monetize these technologies, as most markets prioritize shorter duration storage.

What’s more, there’s no clear standard for defining LDES or measuring its performance. And since lithium-ion batteries already dominate the energy storage market, it could restrict the need for LDES, especially for storage needs below eight hours. The low market penetration of renewables presents another limitation, as LDES only becomes essential if and when renewable sources represent the majority of the energy mix.

For long-duration energy storage to be deployed at scale, the market must recognize and compensate for the unique benefits these technologies provide, such as supplying power during peak demand or maintaining grid stability during periods of high variability.

LDES is pivotal for the decarbonization of the US and international power grids. And moving forward, governments need to enact more policies that catalyze the deployment of LDES and create demand.

An image of a neighborhood along a desert hill

The issue is even more acute in low and middle-income countries where fiscal constraints make it very difficult to connect.

Even in places like China, where companies have been able to build ultra-high voltage transmission lines faster than anywhere else, the country faces challenges making new DC lines interoperable with its regional AC grids, and balancing supply and demand to prevent blackouts and reduce electricity waste.

In regions like Sub-Saharan Africa, where half the population lacks access to electricity, the primary issues with upgrading and expanding the grid are access to capital and governance. In the interim, smaller-scale solutions such as microgrids can help expand energy access, as these places continue to develop and invest in large-scale grid infrastructure.

Although transmission is primarily a policy problem, innovation will help too. For example, what if we could take existing power lines and transmit more electricity through them ? This could help build out electricity capacity while working through the permitting process of building new transmission lines.

There’s no transition without transmission.

TS Conductor is pioneering high-efficiency conductors

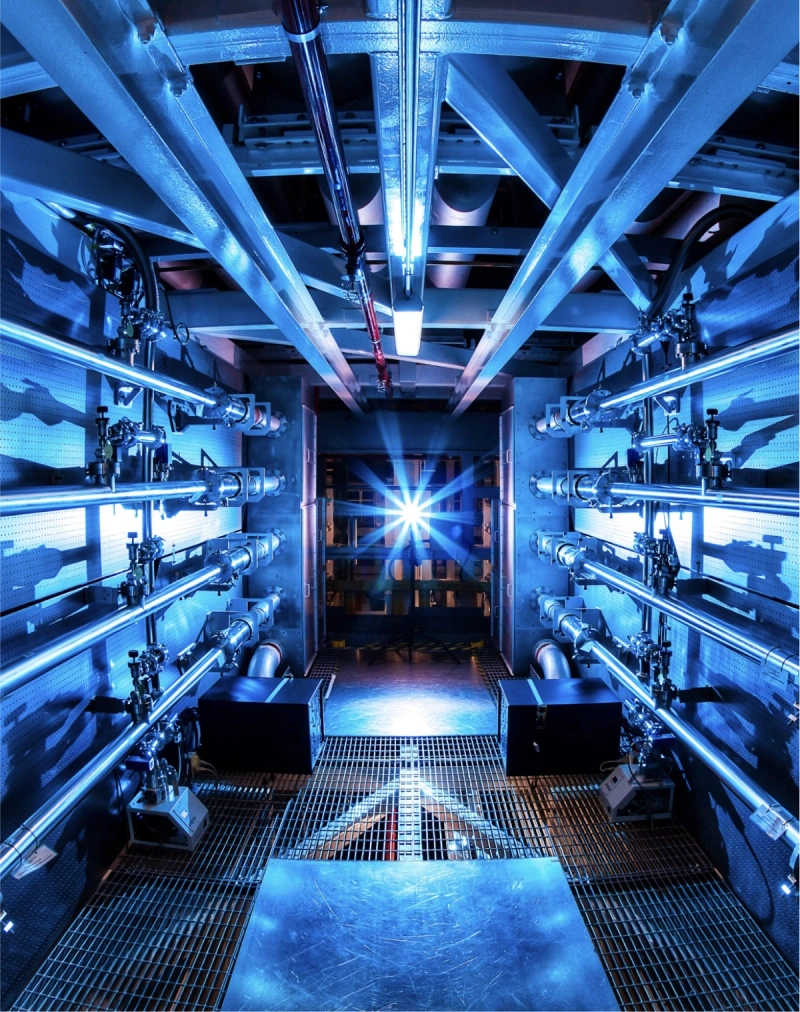

Inside of a NIF preamplifier support structure

There’s another “nuclear” in this story though. It’s called fusion , and it holds even greater promise than everything we’ve discussed so far.

While fission takes atoms apart, fusion pushes them together — or, fuses them. This is the same process that powers the sun, and here on Earth, scientists replicate it with lasers or by pushing plasma around inside a big magnet. If the scientists turn off the lasers or the magnets, the fusion process stops. There is no potential for a runaway chain reaction or meltdown.

Researchers have actually been doing fusion reactions since the early 1900s. But for the last century, fusion had a problem: fusion reactors always took in more energy than they put out. That is, until last year.

In December of 2022, researchers made a historic breakthrough. Scientists at Lawrence Livermore National Laboratory outside of San Francisco achieved the first fusion reaction in history to generate more energy than it took in.

The best analogy here might be Kitty Hawk — both in its importance and infancy. The Wright Brothers’ plane changed history, but it was a far cry from commercial production when it launched into the air.

That’s where fusion is today; still in the research and development stage, where it’s only done in labs, but beginning to move to the domain of real companies putting energy out into the world.

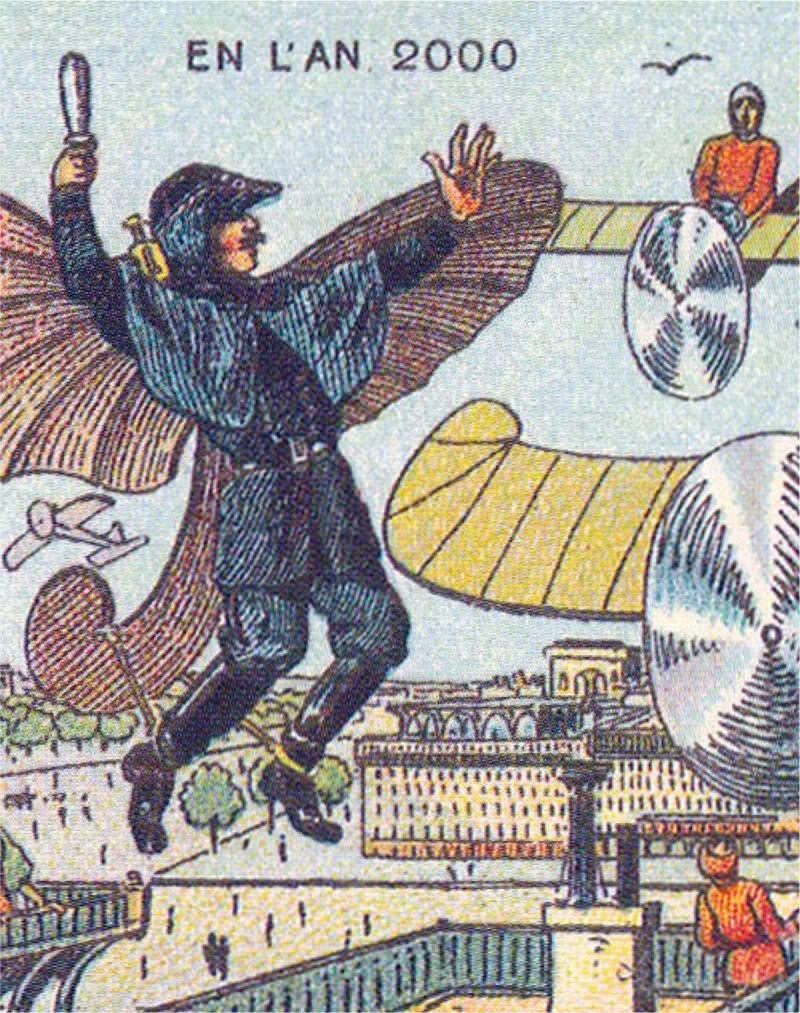

A postcard illustration of flying policemen, which was commissioned for the 1900 World's Fair in Paris

For the 1900 World’s Fair in Paris, a series of 87 postcards were commissioned, each envisioning what France would look like in the year 2000. Most were pictures of transportation — absurd transportation.

Policemen wear winged uniforms, directing traffic in midair while transatlantic travelers sit in undersea buses hitched to humpback whales.

A postcard illustration of an underwater whale bus, which was commissioned for the 1900 World's Fair in Paris

Presumably, the postcard artists never paused to ask some basic questions. Like, how would one domesticate a large sea mammal so it can pull a bus? Or why would it be more efficient to elevate traffic 10 meters off the ground rather than leave it on the Champs-Élysées?

For those of us trying to help usher in zero-carbon ways of moving around , the Paris postcards are a good reminder: Visions of the future are a dime a dozen. But if you haven’t figured out the science or the economics yet, you’ll look foolish.

An aerial view of acres of cropland

We Are What We Eat

Did your parents ever tell you, “You are what you eat”? Maybe they were trying to scare you off of that cinnamon roll or guilt you into putting some broccoli on your plate. Whatever it was, the message was clear: What you put in your body affects your health. Turns out, it also affects the health of our planet.

The food and agriculture sector accounts for 20% of global greenhouse gas (GHG) emissions. Two thirds of that comes from crop and livestock activities, while the rest comes from landfills, deforestation, and land use change.

A farmer harvesting a field of crops

But it’s not just the size of agriculture’s emissions that makes it hard to tackle, it’s the source

. The majority of emissions come from GHGs other than carbon dioxide (CO₂) like methane and nitrous oxide, both of which are more potent warming agents than CO₂. Methane warms the atmosphere approximately 28 times more than an equivalent amount of CO₂ over a century. Even worse, nitrous oxide’s global warming potential is about 300 times that of CO₂ over the same time frame.

Other factors also make these sources harder to tackle than CO₂. For example, technology to capture CO₂ in the air is far more advanced than methane or nitrous oxide capture. Methane and nitrous oxide also originate from a variety of natural sources like wetlands, livestock, and rice farming.

Another challenge of decarbonizing the agriculture sector is that agricultural emissions manifest differently around the world. They’re influenced by geography, which determines what crops can grow where, as well as by cultural attitudes toward food production and consumption. In other words, what works in the United States may not work elsewhere, and vice versa.

India, for example, has the largest cattle herd in the world, due to the cultural significance of cows. In Indonesia, deforestation for palm oil can account for more emissions than the nation’s entire energy sector. In Brazil, deforestation and cattle farming account for the majority of emissions. And in the United States, fertilizer application and nitrous oxide lead the emission profile.

A tractor spreading fertilizer

Nitrogen fertilizer is also remarkably inefficient. About 50% of nitrogen fertilizer applied to soils is actually lost to the environment.

If we can manage nitrogen more efficiently by delivering it to crops with less energy, emissions, and run-off, we can enhance food security and reduce our dependence on imports.

One of the most promising strategies comes from Pivot Bio , a California-based company that uses nitrogen-fixing bacteria to give plants the ammonia they need to grow. Pivot Bio uses microbes in the soil to create a symbiotic relationship with the roots of crops. The microbes consume root exudates, a sugar product expelled by the crop, which gives them the energy they need to convert hydrogen from the air into ammonia.

Pivot Bio is transforming fertilizer

This process could displace the need for synthetic fertilizer entirely, providing more or less nitrogen to the crop as needed without washing away during severe weather. Unlike current methods of producing ammonia, the energy source for this process comes at no cost. In other words, these microbes create a built-in fertilizer factory in the soil.

The Colorado River, which is currently experiencing a severe drought

But the agriculture sector’s reliance on nitrogen isn’t its only problem. It’s also using up water at an unsustainable rate.

In the American Southwest, which is experiencing a severe drought, 55% of the Colorado River’s water is used for cattle feed. And in Southeast Asia, water demand is heavily driven by rice irrigation; in India, for example, over 60% of water demand comes from rice fields. Growing rice in flooded fields contributes significantly to global methane emissions; in fact, rice is the world’s most greenhouse gas-intensive crop on a per acre basis.

It’s also not going anywhere. Just as meat is a vital part of American food culture, rice is a critical component of diets in Southeast Asia and many other parts of the world. And by 2050, rice demand is expected to increase 50%.

That’s why water resiliency has become critical to sustainability efforts, not only to ensure food security but to reduce the emissions that come from excessive water use.

To accelerate low water-use, low-methane rice cultivation technologies, Breakthrough Energy co-founded Rize . Rize works with rice growers to accelerate the adoption of a water-saving irrigation technique called Alternate Wetting and Drying (AWD).

Using what’s called a piezometer to measure water levels, farmers can optimize water usage for rice by alternating between cycles of wetting and drying, reducing their water consumption by roughly 30% and methane emissions as well as by producing more with less, we can spare the need for land clearing to feed a growing, more affluent population.