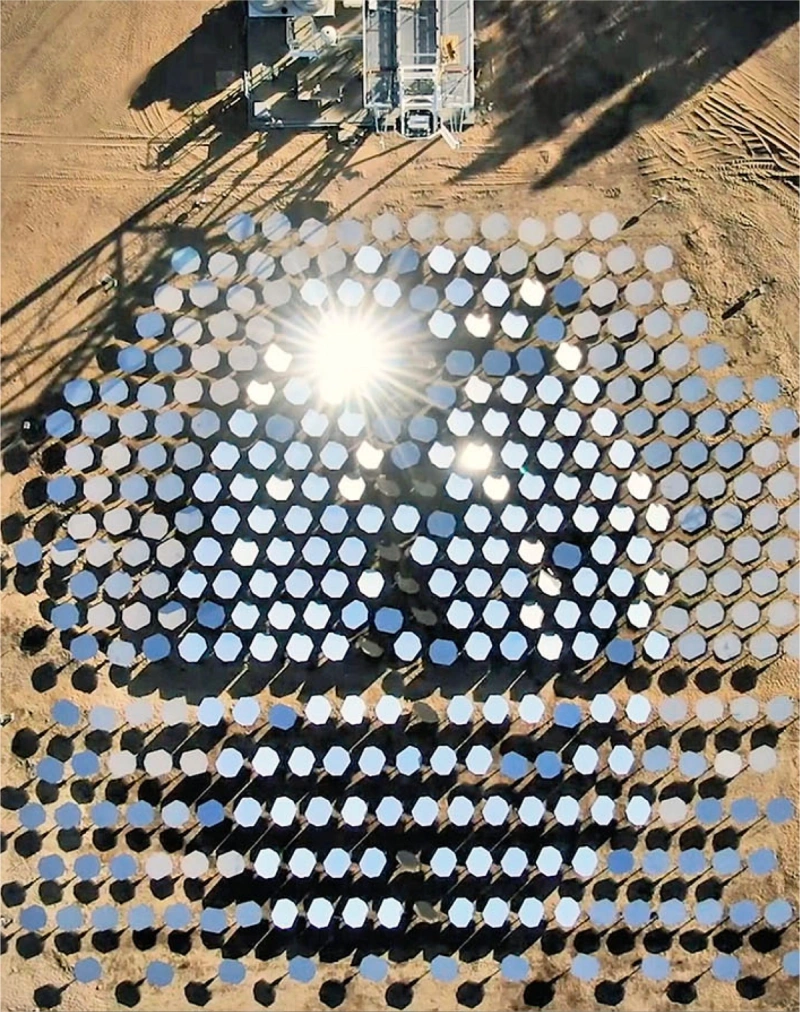

Startup Heliogen uses fields of AI-controlled mirrors to harness the power of the sun.

This is the perfect example of why climate innovation doesn’t happen in a vacuum: technology is important, but policy is often what moves the needle on adopting them at scale.

Even if new green technologies are perfect — which the first electric cars certainly weren’t — they have their limits. The fundamental challenge of inventing zero-carbon products, from electric vehicles to green cement to sustainable jet fuel, is that there’s no natural market for them. Sure, you might get a few wealthy climate advocates to buy them, but without some extra incentive, they won’t catch on.

That’s why the people historically tasked with fixing broken markets — policymakers — are as important as innovators and scientists in achieving a zero-carbon world .

United States

The United States is the second-largest greenhouse gas (GHG) emitter in the world.

1

1

As the United States moves to meet its climate goal of reducing emissions by 50% in 2030, it can simultaneously inspire and incentivize the energy transition in the rest of the world.

USPA Vice President Aliya Haq on stage with presidential advisor John Podesta

First, the good news

American climate policy in recent years has been a rare bright spot in our field. The Energy Act of 2020, the Bipartisan Infrastructure Law of 2021, the CHIPS and Science Act of 2022 (CHIPS), and the Inflation Reduction Act of 2022 (IRA) — all signed into law, three of them with bipartisan support — will help reduce U.S. emissions and drive down green premiums for emerging clean technologies.

Together, these bills will invest at least $500 billion in clean energy — with the potential for the total investment over 10 years to climb to over one trillion, depending on how much demand is created in the private sector.

But much more work remains to ensure that these laws are implemented successfully, as well as to ensure progress in future climate policy. Our U.S. Policy & Advocacy Team aims to cut through it by leveraging our in-house team of experts, our uniquely strong network, partnerships forged through grantmaking, and a longer-term view than workaday politics can often afford.

Looking to 2024 and beyond, our policy team is focusing on multiple fronts . We’re helping agencies implement new funding and tax credits , advocating for more long-distance transmission lines to accommodate increased electrification, focusing policy work on “hard to abate” sectors like agriculture and aviation, and driving the conversation forward around technology-neutral performance standards for electricity, fuels, and manufactured products — to name just a few tracks in which we work.

Takachar's prototype, the “Takavator," a portable machine that turns crop waste into biofuels, carbon-based fertilizer blends, and other valuable bioproducts

At Breakthrough Energy, we try to identify great ideas, long before they are associated with a company, founder, or even a catchy name — and long before they have attracted serious funding.

Why? Because we need to improve on existing technology by an order of magnitude — and we don’t even know yet what that will look like. It’s estimated that nearly half of all emissions reductions in 2050 will come from technologies that have yet to reach the market . The sky-high stakes of the climate emergency mean that we must jump-start innovation at the earliest stages, so that ideas can get into the world faster than they would under normal market conditions.

We do this through three programs.

Wind turbines at sunrise

The Horizon

Today, some of the most promising companies in climate tech are just ideas in universities and laboratories, far from Silicon Valley, in the minds and on the work benches of brilliant scientists and engineers.

Our discovery programs find and foster the people working on those critical, yet high-risk, technologies, and help them develop their ideas before soliciting conventional scaling capital.

Across our first three cohorts , we’re working to help derisk a portfolio of high-potential technologies so that more capital can follow our trail to the most exciting climate solutions of tomorrow.

Badwater Basin in Death Valley National Park, Inyo County, California

All new technologies need to be “derisked,” but especially new climate technologies. Often a company’s first commercial-scale project seems too risky for traditional infrastructure investors. These projects require huge sums of funding, and have highly uncertain returns.

In short, there is a treacherous gap between technology development and technology deployment at large scale. Innovators sometimes call this, “the valley of death.” Most new technologies being deployed in first-of-a-kind (FOAK) projects never make it across.

But what if we could help build a bridge across the “valley of death?” That’s where Breakthrough Energy’s deployment program, Catalyst, comes in.

By using its capital alongside our team’s energy-infrastructure-investing and project-development expertise, we work with innovators to advance their projects from the development stage to funding and ultimately, to construction — starting the derisking process and reducing the technology’s green premium to increase the chances it will make it to the other side of the valley.

The San Francisco-Oakland Bay Bridge lit up a night

Unlike VC and software, or VC and search engines, or VC and social media, VC and climate tech never fit very well together—partially because of a skills gap. Climate tech is a relatively new field, and there aren’t many people with both a hard science background and expertise in building startups.

Successful entrepreneurs often became venture capitalists while chemists and biologists became, well, chemists and biologists, leaving an absence of people who might make informed investments in nuclear fission or carbon-free cement.

A view of the U.S. electrical power grid from space

This is no small task.

It took the United States more than a century just to build the fragmented grid it has today. And in order to reach its climate goals, the United States needs to replace the existing wires and at least double the size of that grid in less than 30 years.

Unlike a lot of the other issues we’ll discuss, transmission is primarily a policy problem , not a technological one. The technology, for the most part, already exists.

But in the United States, it’s hard to build new power lines. The current permitting process is long and convoluted. You need available, connecting parcels of land and communities that are willing to have power lines running through their parks and neighborhoods.

To put this in perspective, a transmission project carrying wind power from Wyoming to California took 18 years to fully permit. We just don’t have that kind of time.

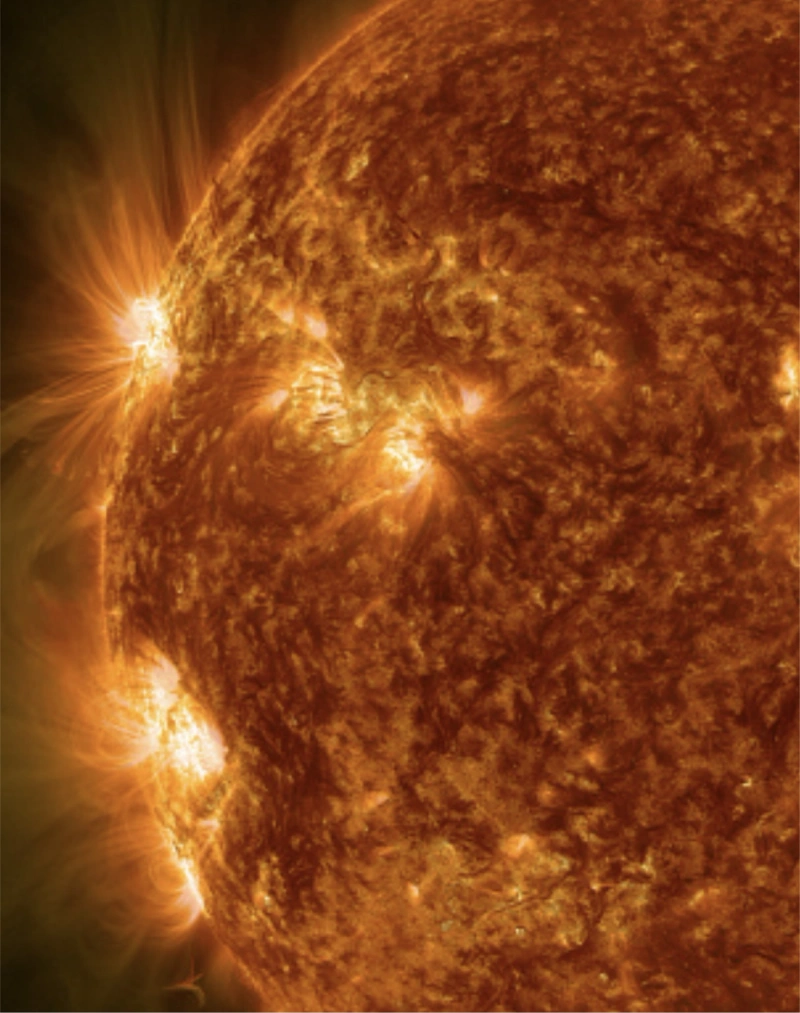

The surface of the sun

The simple answer is they’re going to be vital, but in different ways. Fission — the one you think about when you hear the phrase “nuclear power” — is created by splitting atoms. And it's already an important source of clean energy for countries around the world. Just ask France, which currently gets 70% of its power from it, or Ontario, which gets more than 50%.

That’s because fission can deliver a lot of power with a limited footprint, day and night, all year long, anywhere on earth. No other clean energy source can reliably do that.

There are several organizations working to build next-generation fission reactors that produce far less waste and don’t pose the same risks as older reactors.

In fact, with the help of supercomputers, we can now game out digital simulations of different reactor designs to make sure we’re building the safest reactor possible. These new designs inherently prevent the kind of accidents people tend to associate with fission power. Advanced fission designs have ameliorated some of the cost concerns, too, and companies using these designs will be commercial this decade.

Wilbur Wright gliding down a slope in Kitty Hawk, North Carolina

So why don’t we just forget about the rest and focus on fusion?

First off, while the advancements we’ve made in fusion are astounding, there’s still a lot of uncertainty.

And second, it will be too late. The first fusion power plant will likely hit the US grid by 2030. But the technology probably won’t be ready for widespread adoption for years after that. We can’t wait that long. Fusion could have a profound, positive impact on humanity — providing energy abundance for the world over, but we’ll have to rely on other technologies to ensure that the world is still livable by the time we can make good on fusion’s promise.

Facade of a glass skyscraper

LuxWall

is trying to change that with an incredibly efficient next-generation window. It consists of two specially coated glass panes with a vacuum between them, and it retains four times as much heat as a single-pane window. Think of it like the insulated coffee mug you use in the morning. It keeps things warm on your way to work a lot better than the average cup.

These windows also don’t require a lot of installation labor. Without even taking apart your window frame, an installer can switch out three of your single-pane windows for double-pane ones in the same time it takes to bake a frozen pizza.

As with heat pumps, the challenge here is mass deployment. The world currently has 17 billion square meters of single-pane windows. In South America, Africa, Australia, and much of Asia, more than 80% of windows are single-pane.

Replacing all those windows is a daunting task, to say the least. But it’s more than worth it. Because as long as we continue to use single-pane glass, we are quite literally throwing energy out the window.

Temple Of Pallas, Rome

The majority of cement and steel emissions comes from the process emissions and high-heat approaches that create these materials themselves. Cement is made by heating up calcium carbonate to nearly 1,500°C, and steel is formed by reducing iron ore in massive blast furnaces that can get as hot as 2300° C. Most of these operations are not currently electrified.

That’s partly because these processes far predate electricity; they have been honed over thousands of years. Cement dates back to the Romans, and people were refining steel at the same time wooly mammoths walked the earth. Countless generations have perfected the science of making these materials cheaply, abundantly, and relatively efficiently.

Both cement and steel are, pound for pound, among the lowest carbon dioxide (CO₂) emitters among common building materials. We just use them in such enormous quantities that they end up having this outsized impact on the climate.

Workers mixing cement

We can start with different approaches or chemistries to make cement.

The vast majority of cement used today is “Portland cement,” a mixture of limestone, clay, and other minerals typically burned in a kiln, a recipe first developed in the 19th century. But innovators are finding ways to make cement that do not emit so much CO₂. We already have some promising options.

For example, there’s Brimstone , a startup that has developed a process to make Portland Cement in a new way – from calcium silicate rocks, which have no embedded CO₂ , instead of the traditional limestone. These rocks fit almost seamlessly into the existing cement supply chain, creating just one extra step.

Brimstone is helping reduce emissions in cement production

Exterior of a building made of concrete

A second approach is to stretch cement further. In traditional formulas, cement constitutes about 10% to 15% of concrete. But what if we could get that down to five percent? Or even lower?

Turns out, that’s eminently possible. We just have to add other ingredients known as “supplementary cementitious materials,” or SCMs. We already have several SCMs that can help reduce the amount of clinker (the stony pieces left behind after coal is burned) in cement: fly ash, slag cement, silica fume. One company working in this space is Terra CO2 , which makes SCMs from widely available silicate-based raw materials found near existing aggregate mines.

Another case study is Ecocem , a company in Breakthrough’s investment portfolio in Europe, which has invented ingenious new cement formulations. Many are already being used in Europe's largest infrastructure projects, including the construction of the Olympic Village for next summer's games in Paris. Ecocem's latest technology, “ACT”, is globally scalable and can reduce cement's carbon footprint by 70%, replacing the bulk of the clinker with widely available SCMs and fillers.

Conveniently, all these stretching measures are also cost-saving measures, because cement is the most expensive component of concrete. One team working on this problem from an entirely different angle is a Breakthrough Energy Fellows project called Chement , which has pioneered a new room-temperature electrochemical process that provides an extremely energy efficient way to produce cement with renewable electricity.

An illustration of a cement plant

Capture The Carbon

Another potential intervention is carbon capture and storage, or CCS. Since cement is already so cheap per unit, the Green Premium here is pretty high, and a CCS surcharge can often mean almost doubling the price of cement . And retrofitting existing plants may not make great economic sense, because a new CCS plant costs almost as much as a cement plant — but it’s a good option to have on hand for new construction, especially in emerging markets.

None of these piecemeal solutions are sufficient in and of themselves, because the industry is already so large and established, and these interventions all take a long time

to implement.

On the flip side, many of them work well together, and we should consider stacking them wherever possible.

Unfinished cement and steel structures

Due to the complex value chains of steel and cement, we need leadership from industry players who are willing to scale technologies. This isn’t like electric vehicles, where manufacturers can sell directly to consumers who are open to paying a Green Premium. A new supplementary cementitious material, like TerraCO2 , sells its product to a concrete producer, who sells it to a builder, who may then interface with a consumer, who may or may not want to shoulder the largely-invisible Green Premium.

That’s why it’s crucial that establishment and emerging companies alike commit to scaling new technologies, which has been relatively slow to date, particularly in cement.

There’s no silver — or steel — bullet when it comes to solving the emissions puzzle in manufacturing. But the sheer scale of these industries promises that these solutions, if we make sincere efforts to implement them, will be well worth it.

An aerial view of an open-pit iron mine in Kayseri, Turkey

EV Adoption

The first roadblock to EV adoption involves battery materials .

Today, most batteries are powered by lithium while nickel and cobalt are also crucial components. Current mining and processing of these three minerals is not evenly distributed across the planet.

In fact, more than half the world’s cobalt mining is in the Democratic Republic of Congo while China accounts for 40% of the world’s chemical lithium production — and nearly 80% of the cathode production for batteries. Now imagine what happens if one of those countries experiences a major crisis, like a war, a natural disaster, or trade restrictions.

If the concentration of so many critical minerals in so few places exposes the battery supply chain to geopolitical risk, how can the future of road transportation be battery-powered vehicles?

Croplands damaged by severe drought

What’s more, agriculture is arguably the sector most impacted by climate change. This creates a vicious cycle: Climate change has caused lower yields from crops, in turn increasing fertilizer use and deforestation, which raises emissions and exacerbates climate change even further.

Whatever we do, one thing is clear: the status quo is unsustainable. Not only would inaction mean continued increases in emissions, but it would also lead to dire levels of food insecurity, which has already increased dramatically due to climate shocks and supply chain disruptions.

And yet, up to this point, the resources devoted to decarbonizing the agriculture sector simply don’t reflect its outsized impact on climate change. From 2002 to 2019, total public agriculture R&D spending in the United States, which includes federal, state, and private sector funding of public institutions, declined by about a third, largely due to a reduction in state funding. Although the FY2023 bill increased funding for USDA agencies, bringing it close to early 2000s levels, the American Association for the Advancement of Science states that it was still about six percent lower in 2022 compared to 2003, indicating waning state support for public agricultural research.

Other large nations have outpaced the United States. China, the largest importer of U.S. agricultural goods, and Brazil, a major international competitor with the United States in agricultural exports, both increased their agricultural R&D funding over the past two decades. India, another country with a large agricultural sector, has also increased its public R&D spending.

A farmer herding cattle

However, even if the plant-based alternative market continues to grow, we could still have more cows on Earth by 2050 than we do today. That means we need to focus our efforts on decarbonizing the world’s cattle herd and other livestock.

Policy can play a critical role here by incentivizing the uptake of new and innovative approaches that improve animal nutrition and feed efficiency. It can also accelerate the adoption of new practices, like ArkeaBio’s vaccine.

But tackling methane emissions from livestock requires a nuanced approach, given the pivotal role livestock play in global nutrition and economies. Livestock, particularly dairy, is a lifeline for about a billion people worldwide, providing sustenance and economic stability.

We need to approach this challenge with farmer-centric innovations in feeding, manure management, and general farming practices. Moreover, we need to streamline regulatory standards for methane-reducing products. Investments in these areas will not only mitigate methane emissions but also support farmers in adopting sustainable practices.

An ammonia production plant

ReMo Energy goes after a different part of the fertilizer process: production. In order to make synthetic fertilizer, we have to produce ammonia. A critical step in this process is converting natural gas to hydrogen, known as the “water-gas shift reaction,” which produces GHGs.

ReMo is developing ammonia plants fueled by renewable electricity to deliver nitrogen fertilizer at prices competitive with natural gas-fueled supplies.

The renewable electricity is used to run electrolyzers that make hydrogen from water rather than from CO₂. This process works especially well in the American Midwest, where we see both high ammonia demand and abundant renewable electricity.

We can incentivize better practices through policy, such as offering reduced crop insurance rates for sustainable nutrient management or subsidies to counter potential yield reductions.

A decarbonization roadmap, developed in partnership with experts, could also guide stakeholders towards a climate-conscious fertilizer industry that reduces emissions and ensures a sustainable future.

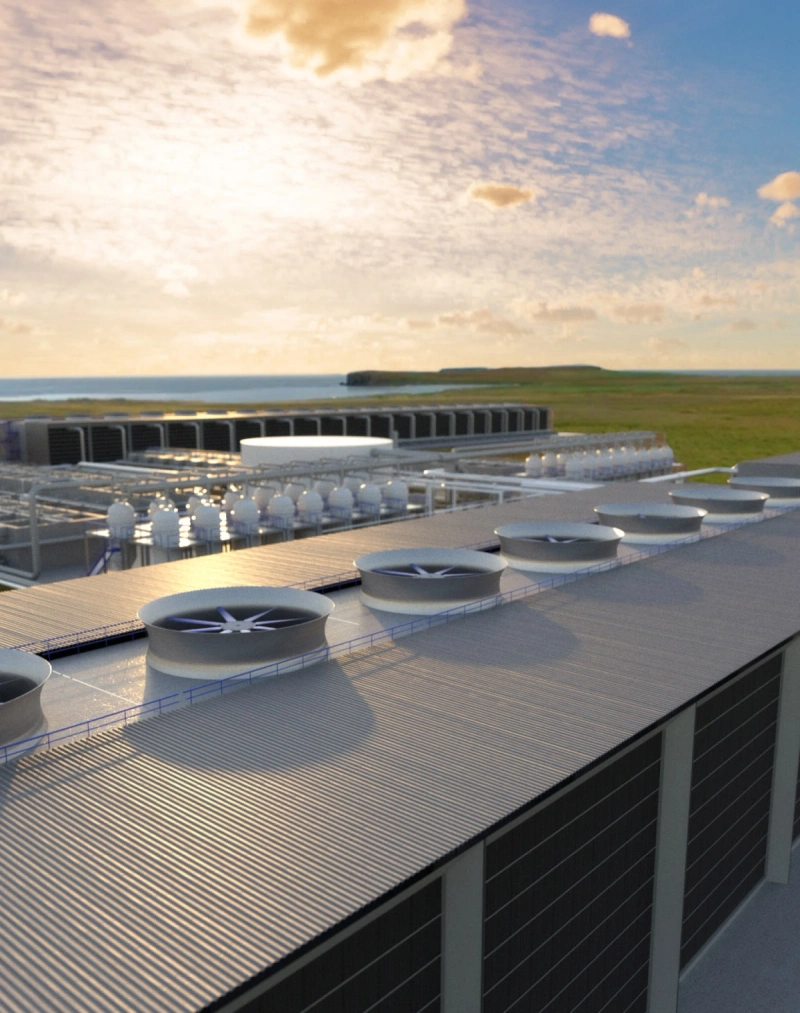

A carbon removal facility

Direct air capture (DAC) is a new method, which can remove CO₂ from the air anywhere, not just at the site of emission.

Of course, engineered removal methods are not the only option. Nature offers avenues as well. Natural carbon removal includes planting trees, preventing deforestation, and managing croplands more efficiently.

Finally, there is a hybrid option that brings together the benefits of engineered and natural carbon removal strategies. This involves burying biomass that would otherwise decay and emit carbon.

While point-source capture has been around a long time, these devices are expensive to buy and operate. And unless mandated by law, companies have little incentive to use them.

We’ve seen some progress in lowering the costs and carbon footprint in this space. Companies like Mantel

, a BE Fellow, have found innovative ways to do point-source capture using less energy and less heat than typical methods, lowering the cost of this technology.

The most promising advancements in this space, however, have come from the carbon removal methods. In addition to preventing CO₂ from entering the atmosphere, we can remove CO₂ already in the air. All three of the aforementioned removal strategies, which we will discuss in detail below, are vital to reducing CO₂ in the atmosphere and reaching our climate goals.

But cost remains the biggest barrier. Today several companies are pursuing practical direct air capture; some of those approaches could have cost entitlements below $100/ton. Yet, while there is some market for carbon capture and sequestration at those levels, widespread willingness to pay is likely significantly lower than that. That means we need more options for carbon removal.

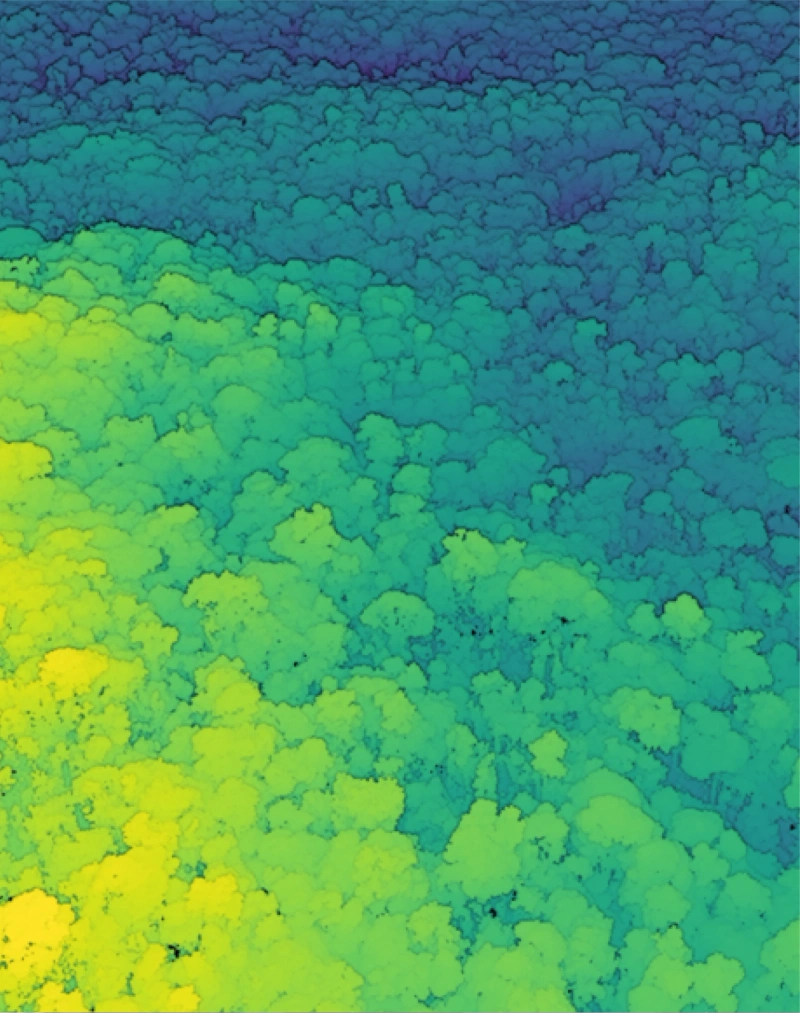

Pachama's forest mapping helps bring transparency to carbon markets

These problems have plagued nature-based removal strategies for years, inviting skepticism from climate experts and investors. But new tools and technologies are resulting in far more rigorous monitoring, reporting, and verification.

Pachama , a company BEV has invested in, uses remote sensing and satellite mapping to develop forest carbon projects and ensure the credibility of carbon credits, harnessing the power of AI to build a modern, scalable, and transparent carbon market.

Soil carbon sequestration has shown great promise as well, but it also struggles with inaccuracies and transparency. Another company we’re working with, Yard Stick , deploys handheld probes and spectroscopy for nearly instantaneous carbon measurement reporting verification. The cost-effectiveness of this method allows for a significant increase in the number of samples taken. This helps address the signal-to-noise challenge that’s been inherent in soil analysis.

Preventing deforestation is also critical to limiting our emissions. Carbon credits are one way to disincentivize deforestation. But what if the deforester you’re dealing with is Mother Nature? Data Blanket , a BEV company, uses AI drone technology to give firefighters an upper hand against wildfires and prevent even further destruction and carbon release.